Cement Pumps

Nordic Geo Support offer our customers high-quality, high-performance products in the field of mixing and conveying and injection technology. The equipment is renowned as sturdy, user-friendly, easy to maintain and reliable. If you can’t find the product that you want listed below, feel free to contact us at Nordic Geo Support.

MAI®400EASY

The MAI®400EASY simplifies the basic grouting process, offering easier use, high mobility and the best price-performance ratio.

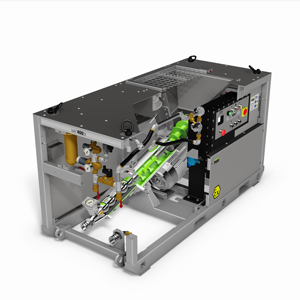

MAI®400EX

The skid-mounted mixing pump MAI®400EX for cementitious grout, specially designed for tough working environments and often environments, such as underground mining and tunnelling projects.

MAI®4EVERLIGHT

Universal machine for mixing, pumping, injection and dry spraying. Ideal for injection works in geothermal applications.

MAI®2PUMP Taurus

For pumping premixed materials, performing renovations (sewers, dam walls, churches, old buildings, etc) and backfilling. Especially suitable for external renders (grain size max. 4 mm), internal plasters (lime/cement based), flowing screeds, concrete renovation materials, fibre-reinforced dry materials in addition to renovation and damp-proofing materials.

Data Recording

Data logging is becoming standard in projects, recording specific information related to the quantities and quality of the materials applied. We offer devices that are suitable for the collection of all relevant data during injection work, re-injection grouting, drill hole filling and backfilling work. This is an essential instrument to provide inputs for the BIM model of the works as well as quality control.

Conveyer/Transfer Pumps

For fully-automated transport of dry premixed mortar from the silo into the feeding hopper of dry mortar processing units.

Delivery pumps

For processing of all machine-compatible, premixed, paste-like compounds and liquid media such as coating materials, flooring compounds, dyes, adhesives and also ready-mixed site mortars. The materials are either injected or pumped.

MAI 4Spark Airless Transfer Pump (PDF)

Flow mixer/Mixer

Automated continuous mixing of dry premixed mortar into a workable compound. For masonry mortar and adhesives. Stationary machines may be fed manually from a bag or from a silo in the case of mixers with silo attachment.

MAI 2MIX Maia Portable Light Mixer Silo Mounted (PDF)

MAI 2MIX Merkur Mobile Horizontal Mixer (PDF)

Cements, Rendering and Plastering Technologies

A broad product range which includes pumping equipment, pneumatic conveying units and screed processing units. Products are available for applying external renders and internal plasters. The range also offers horizontal silo mixing systems and under-silo mixing pumps for the dry mortar applications.

Mixing pumps

For continuously mixing and pumping of machine-compatible dry premixed mortar including external renders and internal plasters based on gypsum, lime or cement.

MAI 4YOU Business Heavy Duty Plastering Machine (PDF)

MAI 4YOU Monophase Silo mixing Technology Plastering machine (PDF)

MAI 4YOU Economy Plastering machine (PDF)

MAI 4EVER Business Heavy Duty For Exterior Renders and Interior Plaster (PDF)

MAI 4EVER Super Heavy Duty For Extreme mixing and difficult materials (PDF)

MAI 4EVER Light – Light Commercial Machines For Mixing, Pumping & Spraying (PDF)

MAI 4Job Business Dismountable Mortar Mixing Pump (PDF)

MAI 4ONESirius Plus Fast Dismountable Mortar Mixing Pump (PDF)