GFRP and Composite Bolting Technologies

Nordic Geo Support is a leading technology supplier with focus on environmentally friendly and sustainable solutions.

For sustainability

Composite technologies can have significant benefits for both the environment and your workforce. One example of this is Glass Fibre Reinforced Polymer (GFRP) rock bolting. Compared to the standard permanent steel rock bolt, GFRP bolts reduce GreenHouse Gas emissions (such as CO2) by up to 60% in manufacturing and transportation. As discussed in the Life Cycle Analysis paper below, GFRP is significantly better than traditional steel bolts in all categories of environmental impact.

GFRP is much lighter than steel so this improves the work environment and increases productivity.

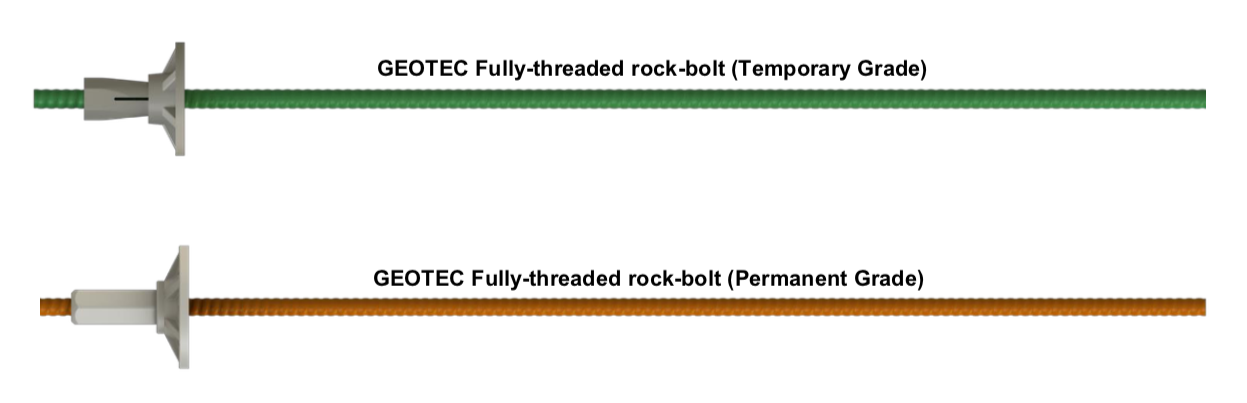

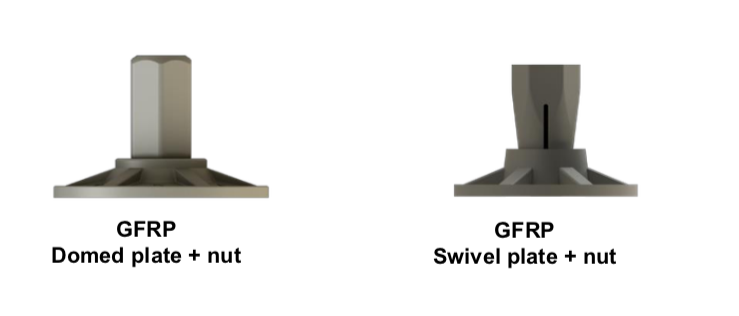

GFRP offers superior durability compared to combination coated steel bolts, with a potential design life of more than 120 years. A variety of GFRP products are available for various applications including continuous thread bars, self-drilling bolts, cable bolts, hollow bars, reinforcement bars and meshes, along with a full range of accessories such as face plates and nuts.

GFRP is also used in temporary applications such as reinforcing ore bodies in mining (to avoid steel contaminating the ore) and tunnel eyes. Nordic Geo Support can offer variants of the GFRP products as cost-effective solutions for these applications.

Advantages include:

- Corrosion resistance

- Ease of cutting

- Electrically insulated

- Flexibility for installation in confined spaces

- High tensile strength

- High torsional strength

- High thermal isolation

- Lightweight (up to 75% lighter than steel)

- A wide range of diameters and shapes in solid or hollow bar

Other composite technologies are also available to meet project design requirements.

More information on the environmental benefits of GFRP can be found here:

Life Cycle Analysis for permanent rock bolts TJ 2017.pdf

More information on the design of rock support with GFRP bolts, including design for loading in shear, can be found here:

Solid Bar Bolts and Anchors

Solid bolts follow traditional drilling and bolting methods and are used in many applications. These offer high ultimate loads and they can be used as a direct replacement for steel bolts (i.e. the same diameter and length). Typical applications include bolting, face support and anchoring as well as many projects where electrical insulation, low weight and cutting to suit on site may be required.

Solid bars are also used for reinforcing tunnel eyes where TBMs or pipejacking machines drive through the walls of shafts.

Hollow Bar Bolts and Anchors

Hollow bars allow for easy post grouting through the centre of the bolt to optimise encapsulation of the bolt. This is necessary for long bolts or self-drilling anchors. Typical applications include face stabilisation, slope stabilisation, spiling and immediate support to loose ground conditions when used in self drilling applications.